About Touch Panel

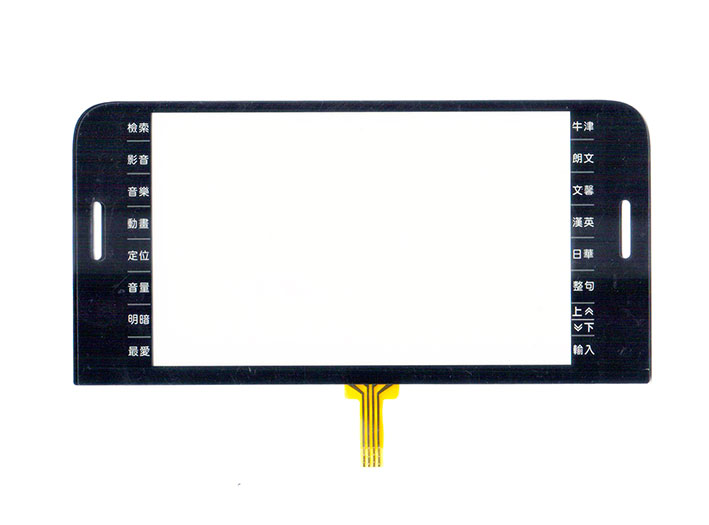

The touch panel/screen was developed in the 1970s for military purposes in the U.S. And has developed into a variety of applications. It played a supporting role in the past, now has become one of the key components, and will even develop towards the direction of integrated industry. Its advantage is to provide the most direct, fast, and effective way to communicate with people and machines, eliminating the complex barriers of traditional computer operation methods, and allowing users to achieve the highest satisfaction of information used in the simplest way. Touch panels are used in a wide range of applications, including portable information, consumer electronics, and communication products: such as PDAs, tablet PCs, digital cameras, information appliances, 3G cell phones, etc.; financial or commercial applications: such as cash machines, sales systems, remote video conferencing, telephone terminal systems; industrial applications: such as factory automation control systems, central monitoring systems, workstation operating systems; public information applications: such as airport, station or shopping mall tour service, presentation, and informed inquiry, etc.

HOW TOUCH PANEL WORKS

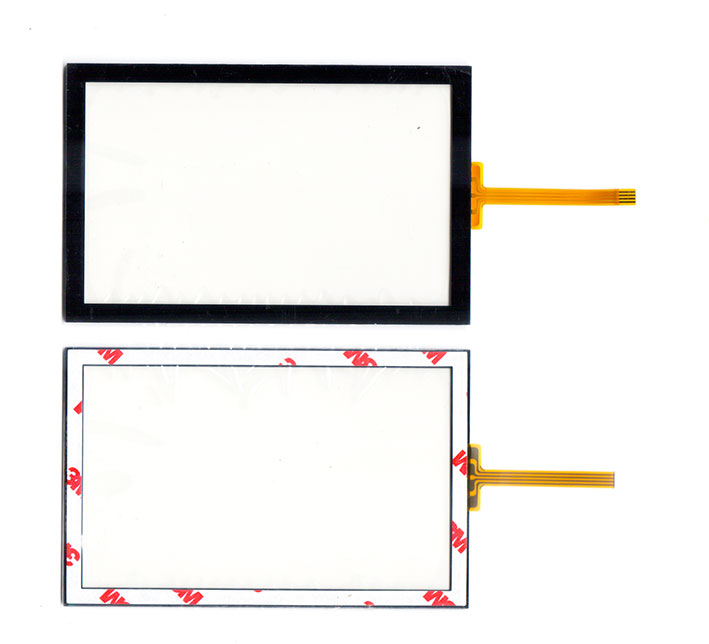

A typical resistive touch panel consists of three layers: top and bottom layers are coated with a transparent conductive film like ITO(Indium Tin Oxide), between the two layers are spacer dots which are usually printed on the bottom layer to prevent the two ITO layers from contacting. Resistive type can be divided into 4-wire and 5-wire according to its performance and universality. 4-wire resistive type has XY axis distributed in ITO film and ITO glass respectively, which will form a broken circuit when the ITO film is seriously scratched and cause the touch panel to be inoperable. The five-wire type is a modified version of the four-wire type touch panel, in which the entire electric field is uniformly built on the ITO Glass and the upper ITO Film is purely a conductor, so when the ITO Film is scratched, only the area cannot be used and other parts can still operate, but if the lower ITO Glass is hurt, it will still cause the Touch Panel to malfunction.

TYPE OF TOUCH PANEL

Types of Resistive TOUCH PANEL

Analog resistive touch panels: the 4-wire touch panel & 5-wire.

Matrix resistive touch panels: a digital resistive.

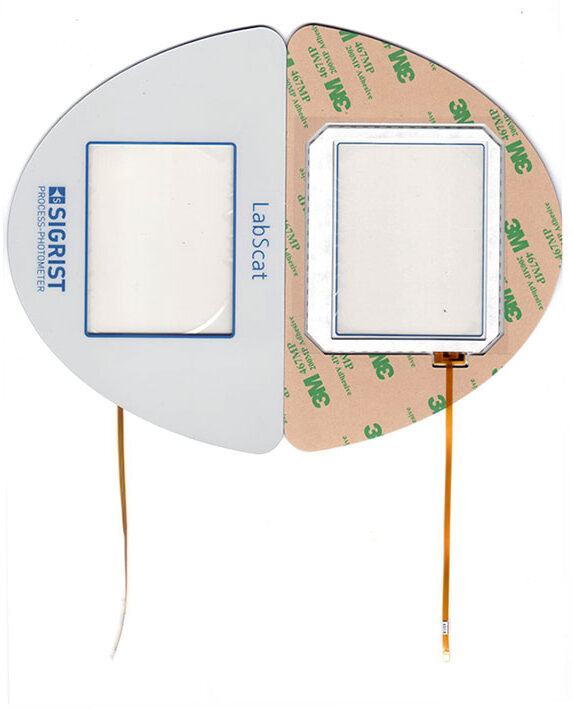

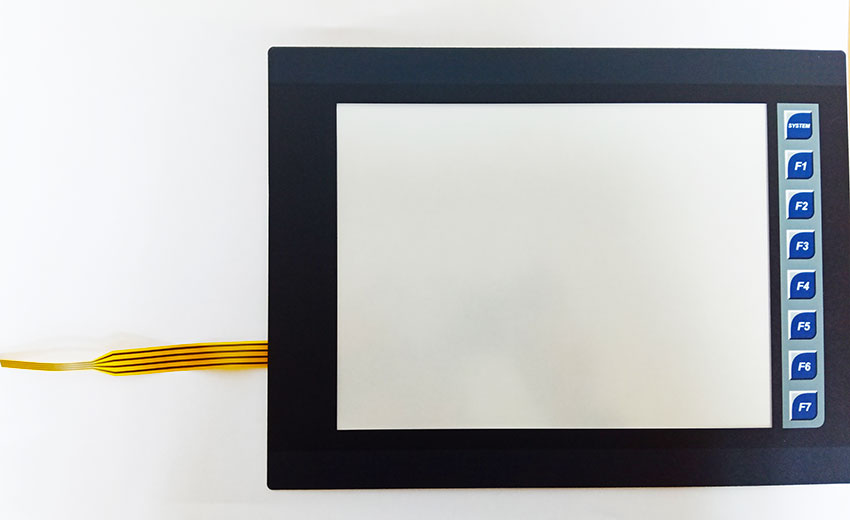

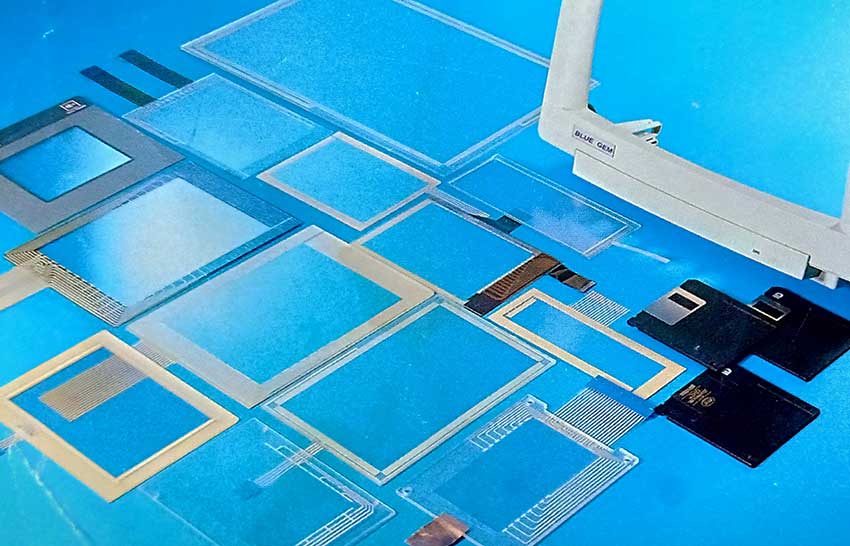

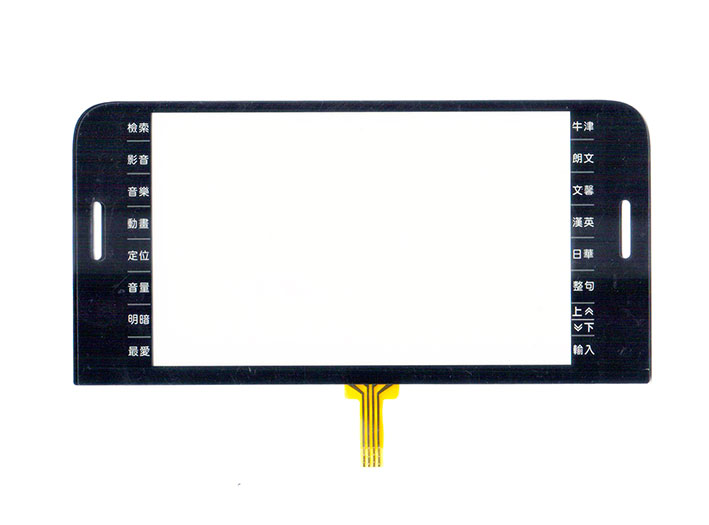

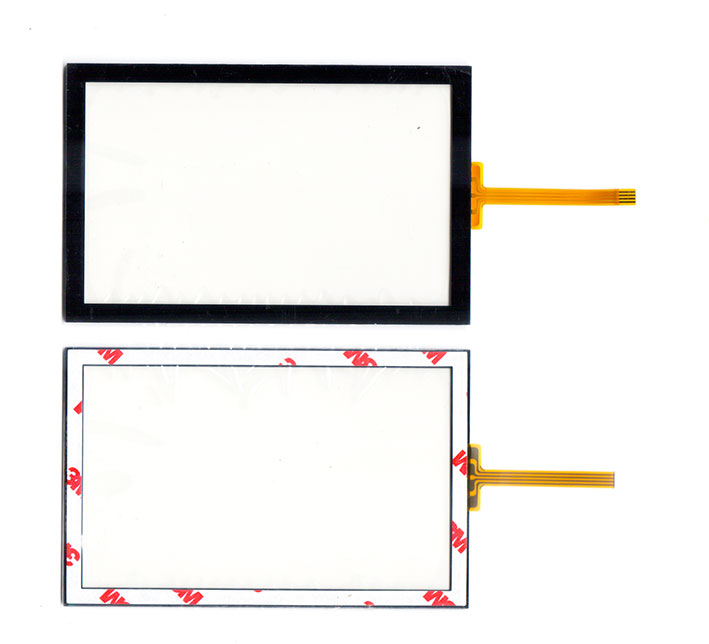

As a professional resistive touch screen manufacturer, MKS produces a variety of sizes of resistive touch panel that satisfies all kinds of equipment application.

TOUCH PANEL ASSEMBLY CHOICE

TOUCH PANEL + FPC + MEMBRANE SWITCH

CERTIFICATIONS

- ISO 9001:2015 QUALITY MANAGEMENT SYSTEMS

- ISO 14001:2015 ENVIRONMENTAL MANAGEMENT SYSTEMS

- IATF 16949:2016 Automotive Quality Management Systems

- UL Certified: UL No. E200944

TOUCH PANEL SPECIFICATIONS | |||||

| Analog 4 wire & 5 wire type | Matrix type | |||

|  | ||||

♦ | Dimensions and Thickness: ITO Film 0.125, 0.178, 0.188mm ITO Glass 0.55, 0.7,1.1, 1.8, 2.0,.2 | ||||

♦ | Structure; Film to Film, Film to Glass, Film to Film with Plastic Back Board | ||||

♦ | Transparency: 75% — 80% | ||||

♦ | Surface Texture: Polished or anti-glare | ||||

♦ | Surface Hardness : 3H with hard coatings for surface protection | ||||

♦ | Actuation Force Range : 2 –4 oz Typical | ||||

♦ | Current and Voltage Rating : DC 5V, 12mA | ||||

♦ | Linearity : 1 to 3% | ||||

♦ | Isolation Resistance : > 50 Mega ohm, at 25V DC. | ||||

♦ | Service Durability: >3 million cycles(Tip R3,Load:300g,Silicone RubberHardness:60) | ||||

♦ | Operating Temperature : 0 °C – +75°C | ||||

♦ | Storage Temperature: -40°C – +90°C | ||||

♦ | Operating Humidity: 60°C, 90% R.H. 240 Hours | ||||

♦ | Flat Surface and Curved Surface both are available. | ||||

♦ | Back plate for the stiffener can be transparent polycarbonate, Glass and harden glass. | ||||

♦ | Back lighting also can be design on Your production | ||||

Standard Products | |||||

Size | Active Area | View Area | Outside Dimension | ||

3.8″ | 55.4 X 63.4mm | 58.4 X 65.9mm | 63.4 X 73.4mm | ||

5.7″ | 83.9X 113.4mm | 86.9 X 115.9mm | 91.9 X 123.4mm | ||

6.1″ | 90 X 121.4mm | 93 X 123.9mm | 98 X 131.4mm | ||

10.4″ | 155.5 X 208.9mm | 158.5 X 211.4mm | 163.5 X 218.9mm | ||

15.1″ | 227.1 X 304.3mm | 230 X 304.3mm | 235.1 X 314.3mm | ||

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.